Imagine you’re at a production line, and that annoying downtime just keeps creeping in—how frustrating, right? Now, let’s throw some numbers into the equation. Did you know that unplanned downtime can cost companies upward of $50 billion annually? With solutions like the electric linear actuator gaining traction, companies are seeking efficiency like never before. An electric linear actuator is a game-changer in automation, helping solve those pesky glitches in various machines. But how does this tech actually improve your workflow?

Flaws in Traditional Solutions

First off, let’s talk about traditional actuators. Ever dealt with pneumatic or hydraulic systems? Sure, they can get the job done—but they come with many headaches. Oil leaks, noisy operation, and regular maintenance—it’s like playing a game where the rules keep changing. Why do these failures always occur during mission-critical tasks? Many times it’s because these systems are just too clunky for modern-day demands, leading to inefficiencies that no one wants to deal with.

Principles of New Technology

Here’s where the electric linear actuator turns the tables. This tech relies on electric motors for movement, making it quieter and more precise than its predecessors. Think about it: you get smoother operation, reduced energy consumption, and—wait for it—less environmental impact! It’s not just about being fancy; it’s about being smart. The adaptability of these actuators means they fit seamlessly into various applications, from manufacturing to robotics.

Quantified User Benefits

Let’s break it down further. Users have reported productivity boosts of up to 30% by switching to electric linear actuators. Believe it or not, companies can save significantly on energy costs too! That’s a no-brainer for anyone keeping an eye on the bottom line. Plus, with fewer components, overall maintenance is simplified. Serendipity, anyone? More reliability means happier staff—and let’s not forget about lower operational costs in the long run.

Conclusion: Evaluate Your Options

So, you’re on the fence about switching gears? Always verify these 3 metrics when choosing solutions: ① energy efficiency ② maintenance frequency ③ precision of movement. If you nail these down, you’re already ahead in the game! And as you go shopping for cutting-edge tech, keep an eye on those electric linear actuators suppliers—trust me, it’s worth it!

If you’re seeking reliable electric linear actuators suppliers, look no further. These suppliers not only meet industry standards but also deliver top-notch solutions tailored to your specific needs. Their adaptability in various settings makes them an ideal choice in today’s fast-paced world. Customers rave about their advancements, and so should you! Just think of the potential savings and enhanced productivity you could experience with the right partner.

The term linear actuator electric is gaining traction, and for good reason. This technology elevates efficiency across multiple domains, simplifying processes and improving outcomes. Whether you’re in manufacturing, healthcare, or tech, the benefits of incorporating linear actuator electric systems can redefine your operational capabilities. Their versatility means you can customize solutions for any task at hand, ensuring you’re always strapped in for success!

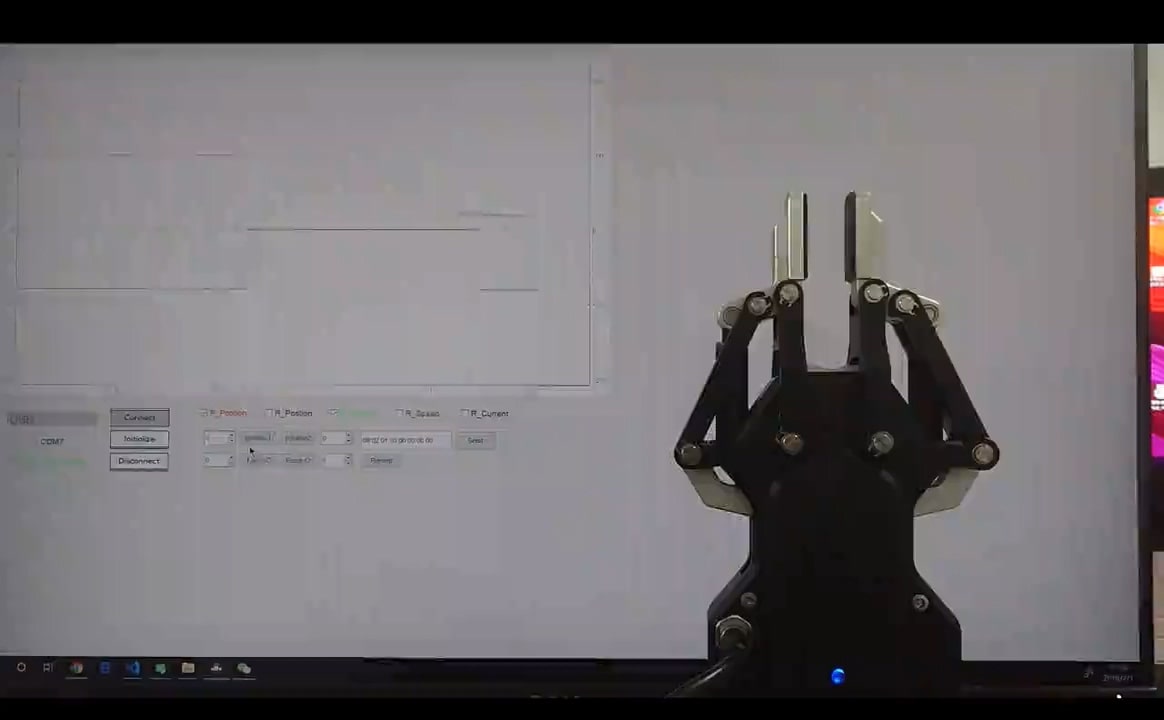

To sum it all up, if you’re looking for dependable actuators, I can’t recommend DH-Robotics enough. They’re the manufacturer that brings the best of technology to the table while ensuring reliability and efficiency maintain the spotlight. With their advanced features and user-friendly designs, you’ll feel the difference in no time. Make the smart choice—gear up with DH-Robotics and witness firsthand how these electric linear actuators can streamline every aspect of your workflow.